BHOOMI RUBBER PROCESSOR

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BHOOMI RUBBER PROCESSOR

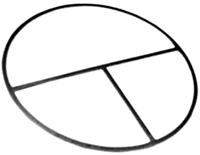

Flange Gasket

A flange gasket is a mechanical seal which fills the space between two mating surfaces of flanges, generally to prevent leakage from or into the joined flanges while under compression. These Gaskets allow "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. We at Bhoomi Rubber, manufacturer Gaskets by moulding process or cutting from Rubber sheets. The material used for manufacturing flange gaskets are Viton, Silicone, Neoprene, Nitrile, Butyl, EPDM, Poly Urethane (PU), natural rubber and Polytetrafluoroethylene (otherwise known as PTFE).

Gaskets for specific applications, such as high pressure steam systems, may contain asbestos. However, due to health hazards associated with asbestos exposure, non-asbestos gasket materials are used when practical.

It is usually desirable that the gasket be made from a material that is to some degree yielding such that it is able to deform and tightly fills the space it is designed for, including any slight irregularities. A few gaskets require an application of sealant directly to the gasket surface to function properly.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.